- Home

- /

- Library

- /

- Reference Guides

- /

- Grading Guide

- /

- Glossary

Glossary

A guide to understanding popular hardwood plywood and veneer face grades.

Hardwood Plywood Terms

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

Annual ring (Annular Ring)

See Growth Ring

Back

Generally a lower grade veneer than that of the opposing side of the same panel when a higher grade face is specified.

Barber pole

Barber pole

A phenomenon in a book matched face wherein adjacent components appear alternately dark and light due to the presence of lathe checks on the loose side of the veneer refracting light and absorbing slightly more finishing material.

Bark Pocket

An area of bark surrounded by wood of normal growth and color.

Blending

Color change that is detectable at a distance of 6 to 8 feet but which does not detract from the overall appearance of the panel.

Book match

Veneer sheets consisting of individual components that are spliced side by side with every other side turned over, creating a mirror image at the joint due to the orientation of the grain coming together at the joints. The more common method of splicing face veneers.

Burl

A swirl or twist in the grain of wood, usually occurring near a knot, but which itself does not contain a knot. Clusters of small pin knots resulting from the development of adventitious buds or branches may or may not be present.

Back to Top

Check

Any fracture of a veneer surface along the grain generally resulting from stresses due to un-even shrinkage during seasoning or acclimatization, often exacerbated when extreme conditions of exterior cold and interior heat and relative humidity occur simultaneously.

Checking

The appearance of checks as described above anywhere on a veneer face. Concentration may be isolated to small areas or widely dispersed over the entire panel surface. Often associated with maple due to the stresses inherent in that genus.

Core

Any substrate upon which a decorative wood veneer face and or back may be applied by some means of adhesion. A core may be fabricated from hardwood or softwood veneers of various thicknesses, or as engineered wood produced utilizing wood fibers (Medium Density Fiberboard – MDF) or wood chips and smaller particles (Particle Board Core – PBC)

Core void

The absence of core material in any component in an inner ply of a veneer core panel as a result of a split, knot hole, damage, or gap between components within a given ply. Generally of more concern when the void occurs directly under the decorative face veneer. Limited in the product standard in Table 7, Summary Of Allowable Openings For Inner Ply Grades For Veneer Core Hardwood Plywood.

Cross bar

Any isolated deviation or concentration of normal grain direction on the surface of a hardwood or decorative softwood face or back veneer usually occurring at approximate right angles to the normal grain direction.

Cross band

A component ply in a veneer core hardwood plywood panel with a grain orientation at an approximate right angle to that of the face, back, and any other inner plies within the core of the panel. Also used to infer the inner ply in a veneer core panel occurring directly adjacent to the face and back of a given panel.

Cross checking

A phenomenon primarily associated with red oak but occasionally with other ring porous hardwoods wherein the early growth regions exhibit small fractures across the grain as a result of expansion or contraction of the substrate in reaction to moisture movement.

Back to Top

Defect

Any manufacturing mark or damage that interferes with the aesthetic appearance or usability of a given panel. Types of defects include delamination, machine or handling damage, dents or impressions (press fault) in a face or back, face or back visible due to excessive sanding (sand-through), core show through, and the like. A natural characteristic such as a knot, split, bark pocket, mineral streak, other color marks or streaks, worm holes, or worm tracks are not considered defects, but rather are limited in occurrence by one of the applicable grades. Allowable but unrepaired or poorly repaired natural characteristics may be considered as defects.

Delamination

A separation of two or more plies in a hardwood plywood panel due to adhesion failure that can result from a number of causes.

Back to Top

Equilibrium moisture content

The moisture content eventually attained in wood exposed to a given environment. Also, the moisture content a given wood component would need to attain to be in balance with its environment.

Back to Top

Face

The better side of a decorative panel intended to be exposed in service.

False quarters

Sheets of veneer consisting of individual components from near the center of the tree and having straight grain produced by conventional slicing of a half log rather than by quarter slicing the log.

Few

A small number of characteristics without regard to their arrangement on a given face.

Figure

Any acute deviation of the normal grain direction in a given tree. Depending on intensity and population in the log, figure may be identified by several esoteric names such as cross bar, swirl, burl, tiger stripe, fiddle back, mottled, ropey, birds’ eye, among others. Note: figure is common in wood to the extent that wood without figure is the exception, not the rule.

Fire rating (fire rated)

A standard classification relative to the rate of flame spread over time in a tunnel test environment. Most wood products meet the classification of “C” in accordance with the National Fire Protection Association, Life Safety Code, NFPA 101.

Fire retardant treated

In this context, any wood panel or solid wood component that has been chemically treated in order to retard the rate of flame spread. Such treated products usually meet the requirements for Class “A” in accordance with the National Fire Protection Association, Life Safety Code, NFPA 101. Generally available with a particle board or medium density fiber core that has been treated as described above. Face and backs are not treated, but any veneer having a thickness less than 1/28″ does not affect the rating of the panel. As of this printing, fire retardant treated veneer core is unavailable and impractical.

Formaldehyde

A pungent, irritating gaseous chemical commonly used in many consumer products, that when off-gassed causes many acute conditions including itchy watery eyes, sore throat, and runny nose. It was once used in large volume to produce decorative and engineered wood components destined for residential or commercial applications, but because it is now considered a carcinogen in the scientific and environmental community, its use in such products has largely been replaced by lower emitting products, or formaldehyde free panels such as Columbia Forest Products Purebond®.

FSC®

Forest Stewardship Council™. An open member-led nonprofit organization that sets independent standards by which forests are audited, protecting them for future generations. FSC uses the power of the marketplace to promote responsible forest management, creating an eco-label that helps consumers identify products from such forests.

Back to Top

Grade

A designation set forth by the Hardwood Plywood and Veneer Association and its membership in the ANSI/HPVA HP-1 American National Standard for Hardwood and Decorative Plywood, including 6 face grades, AA-E, and 4 back grades, 1-4, with each descending grade having more frequent and larger characteristics than the higher grades.

Grain

The pattern, size and direction of the fibers in wood or veneer.

Growth rings

Any of the number of layers of wood added to the stem of a tree during a given growth period, generally annually for temperate species, but not necessarily for all tropical or arboreal species.

Gum spots or streaks

Accumulations of dark, amorphous, water soluble material often found embedded between adjacent growth rings of certain species of hardwoods, most notably American black cherry (Prunus serotina). Source is unknown but thought to be a response by the tree to heal itself from injury.

Back to Top

Half round slicing

An adaptation of rotary cutting, utilizing a stay log that replaces the spindles so that the log half or quarter may be mounted offset from the center. The resulting cut is oriented tangentially to the growth rings to produce a plain sliced appearance, or across the grain and rays, usually in the oaks (Quercus spp.), to produce a rift cut appearance.

Hardwood

General term referring to solid wood or wood veneer originating from one of the broad leaved trees belonging to the class angiosperm. Does not relate to the hardness or fragility of the wood.

Heartwood

The central core of the tree consisting of wood that was once active sapwood but that has been transformed to a neutral state due to the accumulation of extraneous materials and the depletion of oxygen, causing it to take on a generally darker color than that of the outer bands of sapwood.

Back to Top

Knot

Cross section of a limb that transfers to the surface of lumber or veneer as a round or elliptical form having the general appearance of growth rings. The condition of the knot will depend on whether it was alive, dead, or decayed at the time of harvest.

Knot (open)

Opening pronounced when a portion of a knot has dropped out or separated due to seasoning.

Knot (pin)

A knot 1/4″ or less in diameter, with no missing knot material. The center of a pin knot may be dark up to 1/8″ (conspicuous), or natural in color with no dark center (blending or inconspicuous).

Knot (sound)

Knots that are solidly fixed by growth and that retain their place in lumber or veneer.

Knothole

Opening produced when knots drop from the wood in which they were once embedded.

Back to Top

Lap

A manufacturing defect that occurs when a portion of a sheet of veneer splits and subsequently overlaps itself due to uneven moisture movement. A lap may occur in a face and back where it may resemble a split if the errant portion is still intact in the lap or a press dent if the errant portion is missing. It may also occur in a core component wherein it will create a localized thickness difference in the panel that will result in the face or back veneer being sanded off or in the core itself showing through the face or back.

Back to Top

Medium Density Fiberboard (MDF)

Engineered wood panel product consisting of wood reduced to basic lignocellulosic fiber bundles integrated with adhesive and compressed under heat for use as a substrate for decorative hardwood plywood face veneers, paper and plastic laminates, and high pressure laminate (HPL), among others.

Mill run

A production lot of panels produced with the understanding and agreement between buyer and seller that all panels in that particular lot will be shipped by the seller and accepted by the buyer, without regard to usability of any particular panel or portion of any panel due to any manufacturing defect or natural characteristic.

Mineral streak

A generally blue-gray to black elongated discoloration on the surface of solid lumber or decorative veneer.

Moisture content

The percentage by weight of water in wood relative to the weight of the wood with all the moisture removed.

Back to Top

Occasional

Occurring on some, but not all face veneers. Refers to characteristics such as vine caused figure (also called vine mark) that may be present sporadically within a given run of veneer, but not to the extent it creates an objectionable condition.

Back to Top

Particleboard (PBC)

Engineered wood panel product consisting of small wood particles and fiber bundles integrated with adhesive and compressed under heat for use as a substrate for decorative hardwood plywood face veneers, paper and plastic laminates, and high pressure laminate (HPL), among others.

Patch

Any repair to a decorative wood veneer, consisting of synthetic filler or wood veneer inserts.

Plain sliced

Wood veneer cut roughly parallel to the pith of the tree on a tangent to the growth rings, generally having a relatively consistent appearance from piece to piece, and usually producing at least some semblance of a cathedral grain pattern at some point during the slicing process.

Ply

A single sheet of veneer forming one layer in a multi-layered piece of plywood.

Plywood, hardwood

A panel composed of layers of one or more inner plies of wood veneer, MDF, PBC, or other core material joined with an adhesive to a face and back veneer of hardwood or decorative softwood veneer.

Back to Top

Quarter sliced

Decorative face veneer cut on a radial angle to the growth rings of the tree by slicing a quarter log, or a half log as it is reduced to a point near the pith of the tree. Typically, quarter sliced oak (Quercus spp.) veneer will have relatively straight grain with pronounced flake across the growth rings due to the fact that the cut is roughly parallel to the oak rays which are wider than in most other species.

Back to Top

Radial

A line projecting from or converging upon a center of a round object. In wood, the radial plane constitutes a line across the growth rings and parallel to the rays.

Ray

Flattened band of parenchyma cells projecting from the center of the tree to the cambium. Present in all species, but pronounced in some species, particularly red and white oak and alder.

Repair

A patch, shim, or natural or synthetic filler material inserted and/or glued into a face or back veneer so as to achieve a sound surface.

Rift cut (or sliced)

Decorative face veneer cut on a radial angle to the growth rings of the tree by slicing a quarter log, or a half log as it is reduced to a point near the pith of the tree. Typically, rift cut oak (Quercus spp.) veneer will have relatively straight grain with minimal flake across the growth rings due to the fact that the cut is roughly across rather than parallel to the rays.

Rotary cut

Veneer peeled from a whole log set in a lathe and turned against a special knife.

Back to Top

Sapwood

The light colored, active portion of a tree located between the generally darker heartwood and the bark.

Scattered

Relatively uniformly distributed within a given face veneer.

Shake (Ring shake, Wind shake)

A separation of wood structure parallel to one or more growth rings generally associated with traumatic shear stress that may result from wind storms, ice storms, or felling.

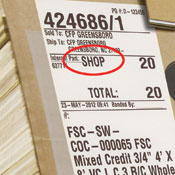

Shop grade (Developed shop)Shop grade (Developed shop)

A common, non-standard industry term broadly defined in the glossary of the HPVA HP-1 standard, but not included as a part of the standard. Generally interpreted and accepted as a panel that is deemed by the final inspector at the producing mill to be less than 100% usable due to a manufacturing defect such as a dent, scratch, or damage, but having at least 85% of the surface area of the panel that is unblemished and assumed to be usable. Shop developed from a normal production run of panels.

Shop, manufactured

A panel manufactured utilizing one or more component(s) that have been previously determined to be damaged to the point they would almost assuredly result in a panel being downgraded to shop in a normal production run. Panels thusly produced are usually provided as “mill run” as agreed upon between buyer and seller.

Slight

Visible on observation but does not interfere with the overall appearance of a given face veneer in consideration of the applicable grade for that particular face veneer.

Slip matched

Veneer sheets that consist of individual components spliced side by side without turning any of them over to form staggered but repetitive grain appearance with all components oriented so that the tight side of each veneer is on the same side of the sheet. Often specified as “Slip Match – Tight Side Out (SMTSO).”

Species

An internationally established and recognized Latin binomial nomenclature used to identify every living plant or animal. As with all such classifications, trees are identified by both genus and species, e. g.: Acer rubrum. Acer is the genus and rubrum is the species, in this case it refers to red or soft maple. Species with the “s” on the end is used for both singular and plural applications. It is always “species.”

Split

Same as check. Separation of wood fiber along the longitudinal direction of the grain, this term is usually associated with such failure isolated to panel ends, although splits may occasionally develop within the field of the panel face.

Split, splice line

A separation occurring between adjacent components in a hardwood plywood panel face, generally resulting from stresses that cause the actual joint to fail, but not the wood fiber within the adjacent components.

Sugar streaks

(See worm track)

Back to Top

Veneer

Peeled or sliced thin sheets of wood used as decorative faces or inner plies in a hardwood plywood panel.

Back to Top

White

A highly generalized term frequently inappropriately used in reference to the lighter color of sapwood in a tree as opposed to the darker color of the heartwood of the same tree. Also used to describe wood of any color, whether heart or sap, that has no added finish material such as stains or paint.

Worm track

Accumulations of light brown parenchyma cells arranged within the tunnels left in the cambium by the larvae of certain species of flies, leaving the image of the trails (tracks) created by these larvae as they continuously consume cambial tissue. Common in maple (Acer spp.) where it is often erroneously called “sugar streak,” and in birch (Betula spp.) where it is sometimes erroneously called “pith fleck.”

Back to Top

NOTE: There are a host of terms used to reference the appearances or processes used in the production of faces, backs, and inner ply veneers or other core components. Many of these terms are colloquial or esoteric, and often misused or at the very least are confusing. The purpose of this glossary is to accurately define these and other often used terms in hopes of making some sense of them.