- Home

- /

- Hardwood Veneer

Hardwood Veneer

The leading supplier of hardwood veneer in North America

ANSI/HPVA defines veneer as “a thin sheet of wood, rotary cut, sliced, or sawed from a log, bolt or flitch.”

Birch, red oak, maple, ash, poplar, cherry and other species of fancy veneer are supplied throughout the decorative plywood, furniture, cabinetry, door and profile-wrap industries.

Types of Veneer

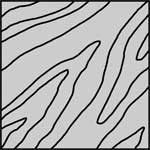

Whole Piece Veneers

Continuous pieces of veneer peeled from a log using a rotary process.

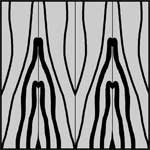

Book Matched Veneers.

Book Matched Veneers.

Every other strip of veneer is turned over. This produces a grain pattern that is matched at the veneer joint.

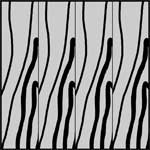

Slip Matched Veneers.

Slip Matched Veneers.

Each strip is laid out side by side (without turning over). This produces a repetitive pattern.

Spliced Veneers.

Spliced Veneers.

Composed of several pieces of veneer varying in width that are glued together to form a whole sheet. The way they are laid out determines the final look of the veneer.

Top Species

[Not a valid template]

Veneer Grades

- Select Veneer is composed entirely of heartwood or sapwood and is matched for both grain, pattern and color.

- Uniform Veneer is also composed of entirely heartwood or sapwood, but is matched for color only.

- Natural Veneer is composed of both heartwood and sapwood and is generally less expensive than select or uniform veneers.

- Paint Grade Veneer has a smooth enough finish so none of the wood grain characteristics show through the paint.

- Stain Grade Veneer is meant to take a clear or tinted stain and still show the natural characteristics of the wood.