- Home

- /

- Library

- /

- Reference Guides

- /

- Grading Guide

- /

- Natural Characteristics

Natural Characteristics

It is common for wood to have naturally occurring anomalies that will show in the wood once peeled or sliced. Many of these natural characteristics add to the appeal of wood and can even enhance its value.

Anomalies

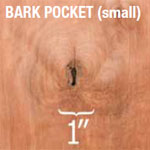

Bark pockets are openings surrounded by bark on a veneer surface, usually associated with a loose or cracked knot. They may have an elliptical shape like those in the photos shown here, or they may have a more rounded shape, depending on the angle of cut.

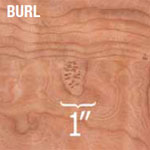

A burl is a cross section of an abnormal growth that occurs on the side of a tree. It may be a cluster of pin knots from adventitious limbs that develop when a limb dies off, or it may be from an injury to a tree. It may occur over a large area, or in a small area as shown here. Burls are limited in the higher grades in the standard.

A burl is a cross section of an abnormal growth that occurs on the side of a tree. It may be a cluster of pin knots from adventitious limbs that develop when a limb dies off, or it may be from an injury to a tree. It may occur over a large area, or in a small area as shown here. Burls are limited in the higher grades in the standard.

Gum is a feature of cherry that does not occur to any great extent in any other domestic species. Gum is a deposit of an amorphous material that is thought to result from the tree attempting to heal an injury. It is dark red in color, and very soft compared to surrounding wood.

Gum is a feature of cherry that does not occur to any great extent in any other domestic species. Gum is a deposit of an amorphous material that is thought to result from the tree attempting to heal an injury. It is dark red in color, and very soft compared to surrounding wood.

The dark part in the center of the cross section of a log is referred to as heartwood. The lighter part that surrounds the heartwood and forms a band of lighter color wood all the way out to the inner bark of the tree is referred to as sapwood.

Mineral streaks are generally blue-gray to black elongated discoloration on the surface of solid lumber or decorative veneer that may be caused by any number of events including injury, disease, growth conditions, nutrients, or even genetics.

Ring porous woods such as red oak produce two-tiered growth rings consisting of coarse textured, darker appearing early wood (springwood) and smooth textured, lighter colored late wood (summerwood).

Ring porous woods such as red oak produce two-tiered growth rings consisting of coarse textured, darker appearing early wood (springwood) and smooth textured, lighter colored late wood (summerwood).

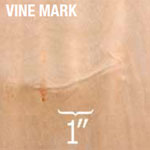

Vine marks are typically isolated, tightly compacted figure features typically resulting when an outside force such as a winding vine compresses the normal growth pattern in that region of the tree.

Vine marks are typically isolated, tightly compacted figure features typically resulting when an outside force such as a winding vine compresses the normal growth pattern in that region of the tree.

Worm track results when certain types of wood cells called parenchyma cells multiply to fill voids left in the cambium as a result of insect larval activity.

Worm track results when certain types of wood cells called parenchyma cells multiply to fill voids left in the cambium as a result of insect larval activity.

Wind shake or ring shake is a traumatic failure of the bonds between adjacent growth rings caused by an outside force such as strong wind, ice, even felling the tree, appearing as a ruptured, feathered, or very rough texture on a veneer surface.

Wind shake or ring shake is a traumatic failure of the bonds between adjacent growth rings caused by an outside force such as strong wind, ice, even felling the tree, appearing as a ruptured, feathered, or very rough texture on a veneer surface.

Knots

A pin knot with a dark center up to 1/8″ in diameter (in most grades) is called a conspicuous pin knot, and is limited by the product standard in grades “AA”, “A”, and “B”.

A pin knot with a dark center up to 1/8″ in diameter (in most grades) is called a conspicuous pin knot, and is limited by the product standard in grades “AA”, “A”, and “B”.

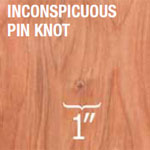

Inconspicuous pin knots have no dark center and are not considered when determining the grade of a sheet of veneer, as long as they do not interfere with the overall appearance of the face.

Inconspicuous pin knots have no dark center and are not considered when determining the grade of a sheet of veneer, as long as they do not interfere with the overall appearance of the face.

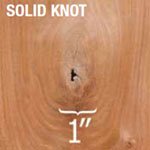

A solid knot is a cross section of a limb that was dead when the log was harvested, usually appearing as dark in color, likely containing cracks and bark that are subject to falling away during manufacturing.

A solid knot is a cross section of a limb that was dead when the log was harvested, usually appearing as dark in color, likely containing cracks and bark that are subject to falling away during manufacturing.

Open knots are permitted on #2 backs and lower, and on “C” grade faces and lower, with some restrictions as outlined in the product standard.

Open knots are permitted on #2 backs and lower, and on “C” grade faces and lower, with some restrictions as outlined in the product standard.

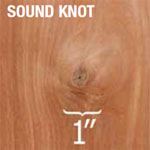

A sound knot usually results when a live limb existed on the log. It will contain growth rings like a smaller version of the tree itself. The knot material is, as the name suggests, sound, and will most likely remain in place throughout the manufacturing process.

A sound knot usually results when a live limb existed on the log. It will contain growth rings like a smaller version of the tree itself. The knot material is, as the name suggests, sound, and will most likely remain in place throughout the manufacturing process.

Figure

Figure is a general term used to describe any deviation from the normal growth of the wood grain, known technically as wavy or curly grain. Figure is so common as to occur in all species to the extent that wood completely lacking in figure is the exception rather than the rule. Slicing or peeling veneer from a log with wavy grain often creates distinctive figure patterns that reflect light differently from the surrounding wood. Some of these patterns are common to the extent they bear familiar colloquial names as shown here.

Tightly compacted, densely populated figure patterns are often called “fiddle back,” and, as the name infers, it is commonly used in musical instruments.

Tightly compacted, densely populated figure patterns are often called “fiddle back,” and, as the name infers, it is commonly used in musical instruments.

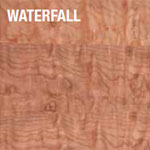

Occasionally, the grain will be compressed into what may be referred to as a waterfall or quilted look.

Occasionally, the grain will be compressed into what may be referred to as a waterfall or quilted look.

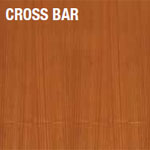

Figure that is clearly visible but relatively isolated on a given veneer surface is defined in the HP-1 ANSI Standard glossary as a cross bar. Cross bar figure is permitted at some level in all face grades.

Figure that is clearly visible but relatively isolated on a given veneer surface is defined in the HP-1 ANSI Standard glossary as a cross bar. Cross bar figure is permitted at some level in all face grades.

Flake, also called “ray flake” is not actually figure in the same sense as the other types shown here, but rather a result of a radial cut veneer that parallels one or more rays that naturally occur in all species. Here we see flake that is common in quarter sliced red and white oak as the rays in these species are quite large in comparison to other species.

Flake, also called “ray flake” is not actually figure in the same sense as the other types shown here, but rather a result of a radial cut veneer that parallels one or more rays that naturally occur in all species. Here we see flake that is common in quarter sliced red and white oak as the rays in these species are quite large in comparison to other species.

Occasionally, for reasons not fully understood, conical indentations, will occur within a developing growth ring in many species of hardwoods, most notably hard maple (Acer saccharum). The indentations are repeated in successive growth rings in a nested fashion that, when the log in which they occur are sliced or peeled as veneer, the resulting figure pattern displayed on the veneer surface resembles, as the name infers, bird’s eyes.

Occasionally, for reasons not fully understood, conical indentations, will occur within a developing growth ring in many species of hardwoods, most notably hard maple (Acer saccharum). The indentations are repeated in successive growth rings in a nested fashion that, when the log in which they occur are sliced or peeled as veneer, the resulting figure pattern displayed on the veneer surface resembles, as the name infers, bird’s eyes.

NOTE: The American National Standard for Hardwood and Decorative Plywood, ANSI/HPVA HP-1-Current Year is the voluntary product standard to which most hardwood and decorative softwood plywood is manufactured in North America. Throughout this publication, any use of the word “standard” is a direct reference to this particular standard. Please see the introduction to the section on the ANSI/HPVA HP-1-2009 Standard Grading Tables on page 22 for further clarification.