- Home

- /

- Products

- /

- Core Products

- /

- Radius™ Bending Plywood

- /

- Europly®

Europly®

European style, European source. World class look.

Trusted Partner in Paged

For over eighty years, Paged has been offering a wide range of products and services to its customers in Europe utilizing wood sourced from woodlands and plantations in Poland.

Columbia and Paged are pleased to annouce a return of Paged BirchPly, a TSCA Title VI ULEF cross-grain as the substrate of the Columbia Europly product line.

Paged BirchPly FSC Mix® [FSC-C01750] substrate is noted for its uniform and homogenous surface and high-ply-count cores.

Europly is smart, visual and responsible.

Easy to machine, with very few voids, the Europly decorative hardwood plywood is durable, rigid and resists splitting and warping. It can be used where special strength and high quality, visual edge is required and desired.

Factory finishing with durable UVWood™ and UV Labcoat™ finish options provide a durable, clear finish in a choice of gloss options.

At Columbia FSC Chain-of-Custody certified factories in North America, this substrate is bonded with the customer’s choice of decorative hardwood veneers in a range of thickness options for a FSC Mix panel construction to meet LEED® project requirements.

Columbia Forest Products has provided fine, decorative hardwood plywood veneer panels to North American fabricators for over 65 years. Columbia’s customers have grown to appreciate the widest product line in the industry from efficient, modern mills where exceptional service and product support are commonplace.

Panel Thicknesses include 1/2″ and 3/4″ with additional thicknesses available. Contact your Columbia representative for current availability.

Features & Benefits

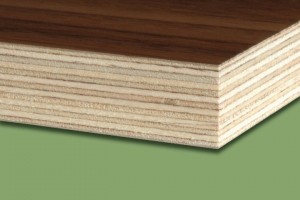

Eurostyle Edge

Europly offers a visually striking edge that designers and architects are demanding for a contemporary, natural appearance.

LEED® Responsible Sourcing Credit – FSC Certified

Europly is available as FSC Mix panel construction at time of order placement. Columbia Forest Products has the largest chain of custody distribution network in the business with LEED® AP support in house to help with project assurance documentation.

CANFER, TSCA Title VI, CARB Compliant

ULEF core construction combined with soy or PVA bonded decorative veneers assures emissions below 0.05 ppm. Complies with LEED® Composite Wood Evaluation for use inside interior envelope.

Columbia Offers Choice

Europly 1/2″ and 3/4″ constructions are typically available with short lead times. For other thicknesses, contact your Columbia sales representative.

Excellent Machinability

Europly provides a virtually void-free construction to help reduce reject rates. Its high-density construction offers great machinability and tremendous screw holding capacity.

Core Properties*

| 1/2″ | 3/4″ | |

|---|---|---|

| Core Construction | 100% Birch | 100% Birch |

| PLY Count (Including Face and Back) | 11 | 15 |

| Glue Type – Core | Phenolic | Phenolic |

| Glue Type – Face/Back Lamination | Soy | Soy |

| Hardness (lbf) | 1,403 | 1,308 |

| Density (lbs/ft2) | 44 | 44 |

| Parallel MOE (psi) | 1,166,170 | 1,226,630 |

| Parallel MOR (psi) | 10,596 | 11,353 |

| Perpendicular MOE (psi) | 1,329,910 | 1,441,010 |

| Perpendicular MOR (psi) | 12,589 | 12,518 |

| Screw Holding – Face (lbs) | 721 | 620 |

| Screw Holding – Edge (lbs) | 511 | 442 |

| Formaldehyde Emissions (ppm) | < 0.05 | < 0.05 |

| Internal Bond (psi) | 278 | 393 |

| Water Absorption (%) | 28.3 | 25.2 |

| Thickness Swell (%) | 7.4 | 6.5 |

| Linear Expansion (%) | 0.09 | 0.06 |

| Width Expansion (%) | 0.12 | 0.17 |

| Weight (lbs) 4′ x 8′ sheet | 57 | 85 |

*Note:

• Test samples were constructed with rotary maple face and back.

• Test results for hardness can differ depending on density of decorative veneer.

• Wood is natural and variable to a certain extent.

• Test data is for informational purposes and does not represent a claim by Columbia that identical panel assemblies meet these properties in the field.