- Home

- /

- Showroom

- /

- Profiles in Quality

- /

- Jaymark Custom Cabinets

Jaymark Custom Cabinets

Innovative problem solvers for over 25 years, Jaymark Custom Cabinets makes healthy cabinet selection is part of the solution!

Back to ProfilesJaymark Custom Cabinets

Huge library of actual samples takes the guess work out of cabinet selection… And future additions!

For Jaymark the decision to go green came out of a desire to solve problems. “About twelve years ago I looked at the amount of trash we were throwing away and said, ‘We need to do something,’ “said Jaymark owner Mark Schwanz. “So the first step was to adopt a serious recycling program that included glass, paper, plastics and wood products.”

Then five years ago Jaymark met a client that helped them take their next step. As it turned out, this client’s children had severe allergy problems, and the parents were looking for cabinetry that would be part of the solution rather than the problem. “I did a little research about what products were out there and found PureBond® hardwood plywood.” Says Schwanz. “At the time it wasn’t readily available in our area. But now it is sold by our main supplier, and about 40% of our clients are requesting formaldehyde-free products for their homes today. Now we use only PureBond® for our box construction.”

Innovative problem solvers for over 25 years, Schwanz began his business as a one-man shop focusing on high end custom work. Trained by a European master craftsman in both metal and wood working, Schwanz began his cabinet business with an emphasis on quality and customer service. The demand for his cabinetry grew so much that today Jaymark is a multi-million dollar company with clients all over the western US.

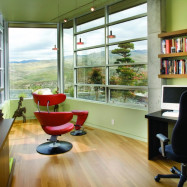

His on-staff team of designers is a large reason for his success. Using the same problem-solving approach he takes with his environmental practices, Schwanz has encouraged his designers to always leave the customer satisfied. “The customer is always right” is an adage still in practice at Jaymark. “Our goal is to give the homeowner what they want. It is, after all, not the designer’s kitchen, but the client’s. Many of our clients know what they want, but perhaps don’t know how to talk about it.” Schwanz’s design team solves this problem by being experts in both appliances and material selection. They also have one of the largest cabinet showrooms in the area.

“We keep a door sample with the profile and finish in our library. At this point we’ve created such a huge library that our designers can pick through that and show the customer an actual door, not just a drawing.” Schwanz also encourages a very thorough communication process between his designers and their clients. Throughout the 10-12 meetings they may have, both client and designer are encouraged to show up with notebooks filled with pictures of what they want or what they envision. The designers in turn create samples and prototypes of the project throughout many stages of the process. They also make it a personal mission to communicate with the customer why they do things the way they do: to give them an appreciation for the fact that Jaymark focuses on the detail and quality work that will make their clients’ cabinets still valuable 5 to 10 years down the road. “We want this to be more than an experience of just picking out cabinets. We made the decision NOT to cheapen up our cabinets, as it’s the little details that make the difference. While we do try to better our processes, we never want to reduce our quality. We’ve fought outside factors to remain this way.”

Their quality is obvious. Their highly automated shop manufactures practically everything they sell, which gives them ultimate control over quality and deadlines. What’s more, they not only offer green products, they live green, using energy saving techniques, reducing waste, and listening to their clients’ need for sustainable, healthy products.

Jaymark’s clientele consists of about 99% residential projects. In turn, his clients care about their home environments and are making the choices necessary to have a healthy interior environment. What’s more, all Idaho state government buildings are now required to be LEED® certified, so the demand for VOC-free products is on a steady increase.

Problem solved!