Helping our Drivers Succeed

- December 9, 2021

- •

- by Columbia Forest Products

“To be a great supplier, you must be a great customer.” — Unknown

By now, you’ve probably read and seen the endless stories about port backups, truck driver shortages and challenging conditions around moving goods throughout the country.

Columbia’s Logistics Director, Brandie Rader, is using her ample experience and some creative new strategies to make delivering our products a more appealing choice for drivers across the country. She’s been involved in Columbia operations for 17 years and grew up with a father who ran his own trucking company.

“We want to be known as the ‘Shipper of Choice’ for anyone who handles a load for us,” said Brandie. “It’s one thing we can do to help us gain the attention, favor and loyalty of the drivers we need right now, and it’ll pay dividends into the future.”

Brandie and her team are looking for all sorts of new and creative solutions to assure that our panels get to market.

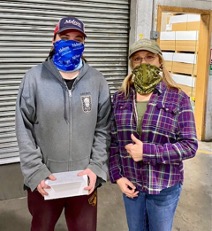

In this photo, Jody Engelbrecht, Traffic Coordinator, is presenting an appreciation gift to a driver from Melton Truck Lines who is committing to handling a scheduled, dedicated route for our Klamath Fall, Oregon facility.

Brandie explains that it’s one thing to have transactional, “spreadsheet” relationships with suppliers and vendors, and it’s something totally different to value and support the individuals who are doing the work for them.

Brandie explains that it’s one thing to have transactional, “spreadsheet” relationships with suppliers and vendors, and it’s something totally different to value and support the individuals who are doing the work for them.

“We don’t employ our own drivers at Columbia,” said Brandie, “so we take it upon ourselves to make sure the folks who show up to deliver our plywood in a careful, efficient and safe manner are treated as a part of our extended family. This springs from living our company values and our focus on business realities.

“We know the pressure these drivers are under, the regulations and policies they have to comply with, and that time is their enemy. We’re doing things to make them more successful at accomplishing their duties while treating them with hospitality and respect,” she added.

The company celebrated a “Driver Appreciation Week” this fall, where gift bags were presented when trucks were being loaded. A range of ongoing projects are being rolled out that are designed to give the drivers an efficient and personalized experience when they’re at a Columbia facility.

An electronic system is being implemented which will operate as an air traffic control center. Drivers, loaders and logistics managers will be able to monitor and respond to things that might delay a truck’s departure.

When they arrive, drivers will be able to check in through an electronic kiosk. It shows all receivers and loaders that they have arrived onsite. From there, they can pick their preferred communication (CB or cell) from our receivers/loaders and will be prompted to proceed to their designated space for loading or unloading.

While at the facility, drivers will be able to relax, catch up on calls or computer time and enjoy a cold drink and snack.

“We want to use this system to make the driver experience something they can count on and look forward to,” said Brandie. “If they can leave our mills on time (or ahead of time) with a little less stress and a smile on their face, they’ll be in a better position to execute their routes on behalf of Columbia and our customers.”

Brandie noted that the information the system captures will help Columbia identify areas for improved performance throughout its shipping and packing areas.

“Every minute we can save a driver is a minute they get back. We’re aiming to get these people back on the road with the focus of a NASCAR pit crew.”